Your Grinding wheel ring test images are ready. Grinding wheel ring test are a topic that is being searched for and liked by netizens now. You can Download the Grinding wheel ring test files here. Find and Download all free photos and vectors.

If you’re looking for grinding wheel ring test images information connected with to the grinding wheel ring test interest, you have visit the ideal site. Our site always provides you with suggestions for seeing the highest quality video and picture content, please kindly surf and locate more enlightening video content and graphics that fit your interests.

Grinding Wheel Ring Test. Grinding wheels must be inspected and ring-tested before they are mounted to ensure that they are free from cracks or other defects. Visually inspect it for cracks chips and other damage. The ring test is designed to detect any cracks in a wheel. Grinding experts call this the ring test and its something that should be done before mounting any wheel to an arbor.

Bench Grinders Choosing The Right Wheel Bench Grinder Bench Grinders Woodworking Power Tools From pinterest.com

Bench Grinders Choosing The Right Wheel Bench Grinder Bench Grinders Woodworking Power Tools From pinterest.com

Ring sound good wheel dull sound cracked wheel and replacement of wheel required. B Give it a ring test to make sure it is suitable for use. Here is a quick easy method to ring test a grinding wheel for a bench grinderThis will prove that there are no hidden defectscracks that could literall. How to Inspect Test an. Of the grinding wheel. They can contain microscopic cracks in them which will cause them to explode at high speeds and send shrapnel flying across your workspace in all directions.

A 18 in or less B No less than 18 in C ¼ in.

Side grinding Wheel Grooves Do not gouge wheel by grinding in one spot Restrictions Do not grind aluminum brass copper or wood Ring Test Check maximum rotational speed ring test new wheels before installing DO NOT MAKE ADJUSTMENTS WITH WHEEL IN MOTION 45 45 45 45 RING TEST TAP WHEEL 1-2 FROM PERIPHERY 45 EACH SIDE OF. Ring Testing Wheel Cover Grinder Gauge 18 Work Rest Grinder Gauge 14 Tongue Guard. Visually inspect it for cracks chips and other damage. Its Not As Convoluted As You Might Think When You View It In True Color It can seem like there are more non-woven. When you need to put a new wheel on your grinder what should you do with the wheel first. B Give it a ring test to make sure it is suitable for use.

The wheels should be tapped about 45 degrees on each side of the vertical centerline and about 1 or 2 inches from the outer edge of the wheel. One method of grinding wheel inspection is called ring testingOSHAANSI and the grinding wheel manufacturers require this method of grinding wheel inspectionIt must be performed BEFORE the wheel is mounted on a grinding machineRing testing depends on the damping characteristics of a cracked wheel to alter the sound emitted when the wheel is tapped lightlyIt. Always use a wheel with a center hole size that fits snugly yet freely on the spindle without forcing it. Sounding the abrasive wheel. Take care not to overtighten the retaining nut and flange that holds the wheel onto the grinder as applying too much torque can cause the wheel to crack.

Source: newmetalworker.com

Source: newmetalworker.com

Make certain the spindle guard that covers the spindle nut has been properly reinstalled on your. Wheels should be tapped gently with a light nonmetallic instrument. How much of a gap should there be between the work rest and the face of the grinding wheel. A 18 in or less B No less than 18 in C ¼ in. Products Services See also.

Source: pinterest.com

Source: pinterest.com

Visual Inspection and Ring Test Hammering Test for grinding wheels Visual Inspection Perform visual inspection and check on the following issues before mounthing wheel. C The RPM of the grinder is als twice that of the grinding wheel. Products Services See also. They can contain microscopic cracks in them which will cause them to explode at high speeds and send shrapnel flying across your workspace in all directions. A versatile clamp allows horizontal and vertical adjustment of the.

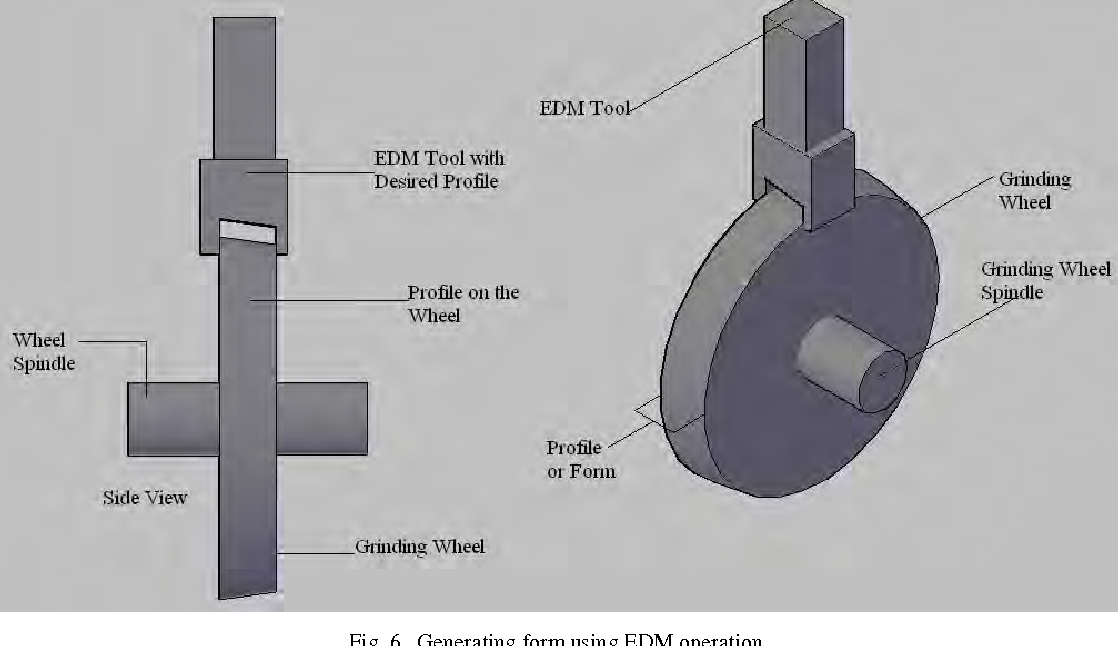

Source: semanticscholar.org

Source: semanticscholar.org

Wheels should be tapped gently with a light nonmetallic instrument. B Give it a ring test to make sure it is suitable for use. Ring Testing In addition to Speed Testing and Balance Testing your grinding wheels MachB performs Ring Testing on every wheel that passes through our shop Ring testing is a manual test that is used to detect defects in bonded grinding wheels A wheel that emits a ringing sound when lightly tapped with a tool is likely undamaged and ready to be used. A versatile clamp allows horizontal and vertical adjustment of the. If its a new wheel straight out of its packaging just put it right on the grinder.

Source: researchgate.net

Source: researchgate.net

Sounding the abrasive wheel. Make certain the spindle guard that covers the spindle nut has been properly reinstalled on your. Ring Testing In addition to Speed Testing and Balance Testing your grinding wheels MachB performs Ring Testing on every wheel that passes through our shop Ring testing is a manual test that is used to detect defects in bonded grinding wheels A wheel that emits a ringing sound when lightly tapped with a tool is likely undamaged and ready to be used. When you need to put a new wheel on your grinder what should you do with the wheel first. Wheels should be tapped gently with a light nonmetallic instrument.

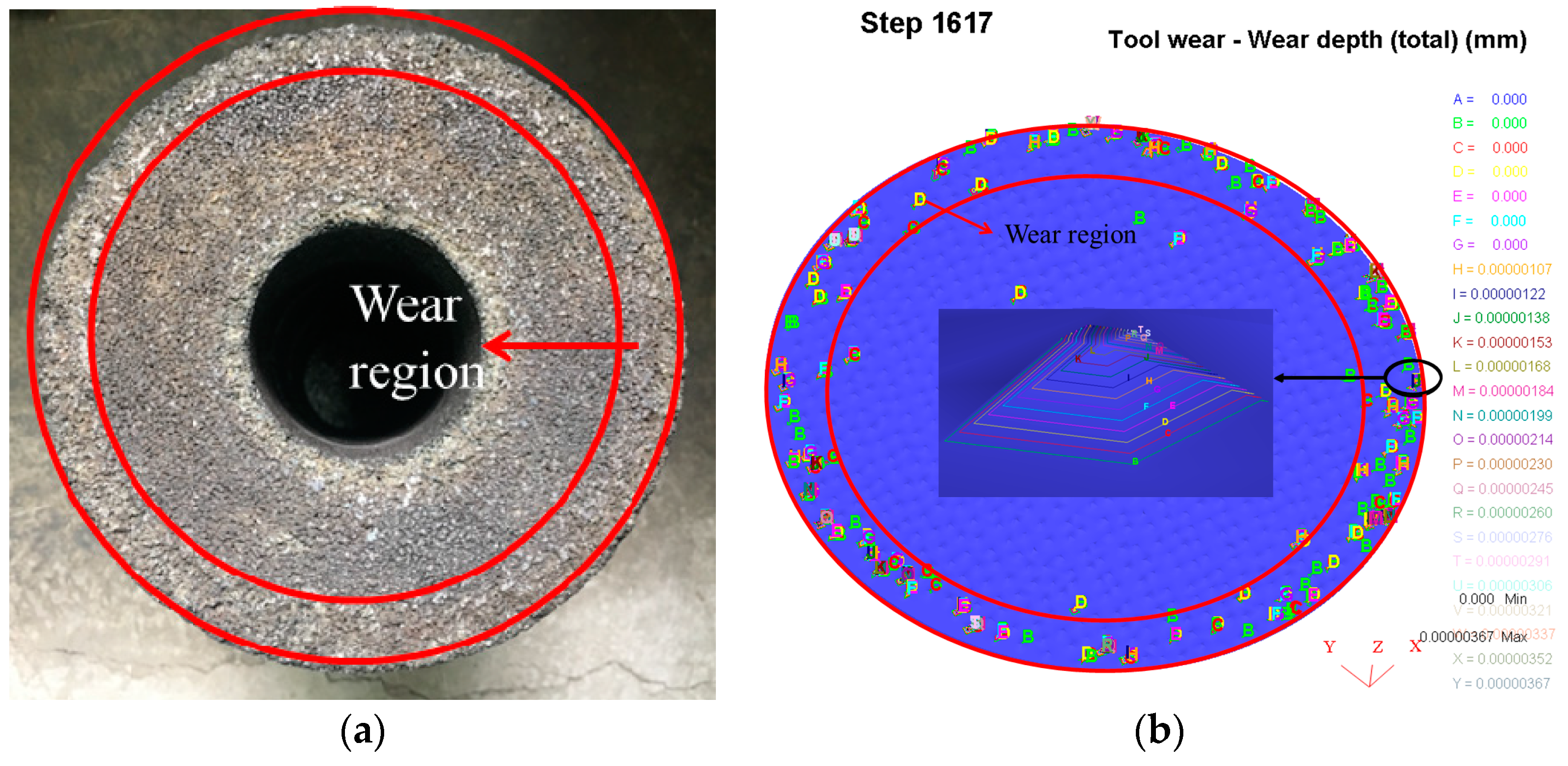

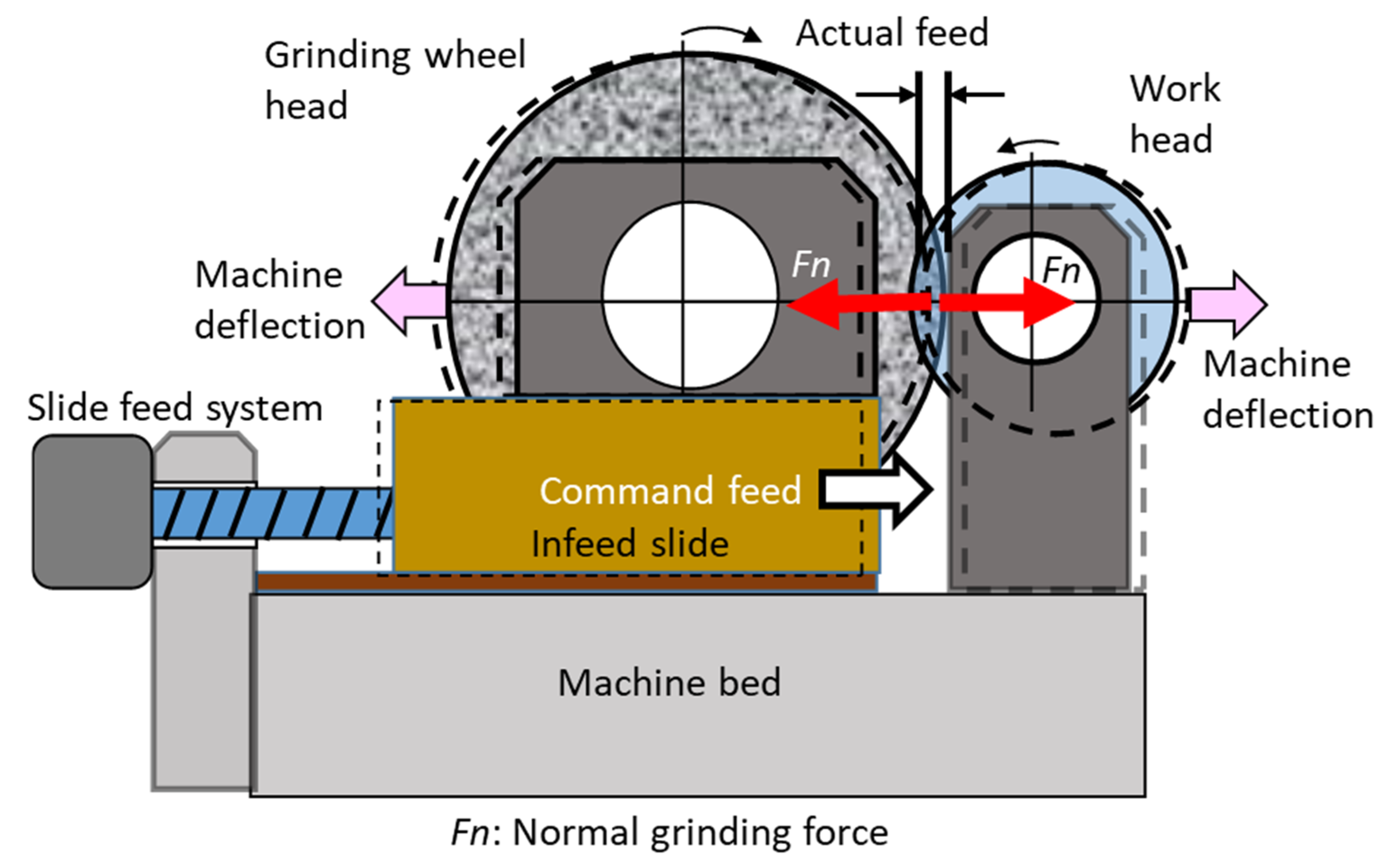

Source: mdpi.com

Source: mdpi.com

Grinding wheels must be inspected and ring-tested before they are mounted to ensure that they are free from cracks or other defects. C The RPM of the grinder is als twice that of the grinding wheel. How to Inspect Test an. Of the grinding wheel. Wheels should be tapped gently with a light nonmetallic instrument.

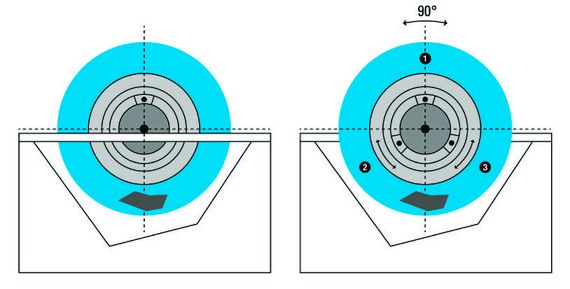

Source: grinding.ch

Source: grinding.ch

The wheels should be tapped about 45 degrees on each side of the vertical centerline and about 1 or 2 inches from the outer edge of the wheel. OSHA Ring Test Grinding Wheels. D None of the above. Of the grinding wheel. Maintain the tool rest within 18 inch of grinding wheel mount the grinder securely as the wheel wears down readjust the tool rest and tongue guard.

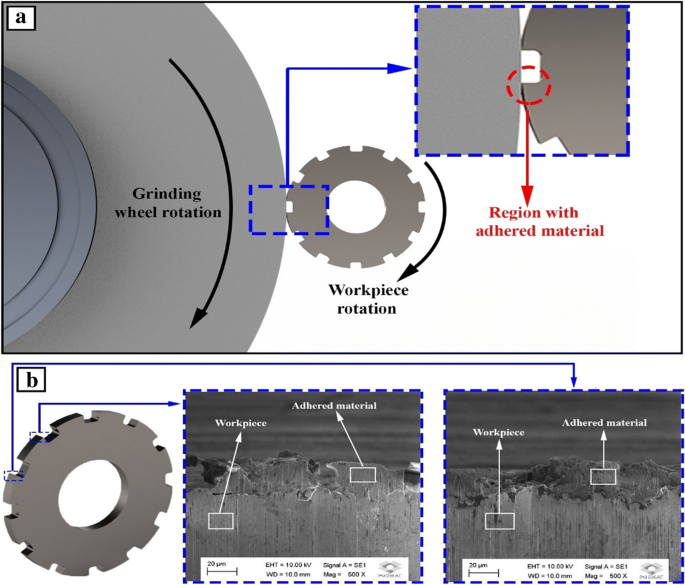

Source: link.springer.com

Source: link.springer.com

Do the ring test. Always use a wheel with a center hole size that fits snugly yet freely on the spindle without forcing it. Cracking chipping or damage Label and abnormality Foreign substances on the flange connection surface Propeller-shaped strain for cut off wheel Ring Test Hammering Test. A 18 in or less B No less than 18 in C ¼ in. Rotate the wheel 45 degrees and repeat the test.

Source: osha.oregon.gov

Source: osha.oregon.gov

Its Not As Convoluted As You Might Think When You View It In True Color It can seem like there are more non-woven. A 18 in or less B No less than 18 in C ¼ in. The wheels should be tapped about 45 degrees on each side of the vertical centerline and about 1 or 2 inches from the outer edge of the wheel. Cracking chipping or damage Label and abnormality Foreign substances on the flange connection surface Propeller-shaped strain for cut off wheel Ring Test Hammering Test. The wheel should be dry and free of any foreign material.

Grinding wheels must be inspected and ring-tested before they are mounted to ensure that they are free from cracks or other defects. When you need to put a new wheel on your grinder what should you do with the wheel first. One method of grinding wheel inspection is called ring testingOSHAANSI and the grinding wheel manufacturers require this method of grinding wheel inspectionIt must be performed BEFORE the wheel is mounted on a grinding machineRing testing depends on the damping characteristics of a cracked wheel to alter the sound emitted when the wheel is tapped lightlyIt. How much of a gap should there be between the work rest and the face of the grinding wheel. D None of the above.

Source: pinterest.com

Source: pinterest.com

How much of a gap should there be between the work rest and the face of the grinding wheel. A versatile clamp allows horizontal and vertical adjustment of the. The wheel should be dry and free of any foreign material. Grinding experts call this the ring test and its something that should be done before mounting any wheel to an arbor. Non-woven Convolute GP Wheels– 63642553754 Supplier.

This is also called a ring test. The wheel should be dry and free of any foreign material. Take care not to overtighten the retaining nut and flange that holds the wheel onto the grinder as applying too much torque can cause the wheel to crack. To perform the ring test wheels should be tapped gently with a light nonmetallic implement such as the handle of a screw driver for light wheels or a wooden mallet for heavier wheels. The ring test is designed to detect any cracks in a wheel.

Source: mdpi.com

Source: mdpi.com

How much of a gap should there be between the work rest and the face of the grinding wheel. How much of a gap should there be between the work rest and the face of the grinding wheel. All safety micro switches are mounted in an enclosed housing with an enclosure rating of IP 67. D None of the above. Cracking chipping or damage Label and abnormality Foreign substances on the flange connection surface Propeller-shaped strain for cut off wheel Ring Test Hammering Test.

Non-woven Convolute GP Wheels– 63642553754 Supplier. The ring test is designed to detect any cracks in a wheel. Grinding wheels must be inspected and ring-tested before they are mounted to ensure that they are free from cracks or other defects. Rotate the wheel 45 degrees and repeat the test. One method of grinding wheel inspection is called ring testingOSHAANSI and the grinding wheel manufacturers require this method of grinding wheel inspectionIt must be performed BEFORE the wheel is mounted on a grinding machineRing testing depends on the damping characteristics of a cracked wheel to alter the sound emitted when the wheel is tapped lightlyIt.

Source: semanticscholar.org

Source: semanticscholar.org

How to Inspect Test an. The Ring Test Grinding wheels are breakable and can be extremely dangerous if used damaged. They can contain microscopic cracks in them which will cause them to explode at high speeds and send shrapnel flying across your workspace in all directions. When you need to put a new wheel on your grinder what should you do with the wheel first. Ring sound good wheel dull sound cracked wheel and replacement of wheel required.

A stable and undamaged wheel will give a clear metallic tone or ring 33 Related Question Answers Found. Grinder Wheel Types 3 Topics Grinder Abrasive Wheels Grinder Cut Off Wheel Other Grinder Wheels Grinder Ring Test 2 Topics Perform Grinder Ring Test Grinder Ring Test Results and Failure Grinder Wheel Speed Replacing Grinder Wheels Grinder Typical Guarding Grinder Flanges Grinder Blotters Work Rest Grinder Grounding Proper PPE -Grinders Grinder Inspections. Maintain the tool rest within 18 inch of grinding wheel mount the grinder securely as the wheel wears down readjust the tool rest and tongue guard. C The RPM of the grinder is als twice that of the grinding wheel. See How to Perform the Test below for more information.

Of the grinding wheel. If its a new wheel straight out of its packaging just put it right on the grinder. Grinding wheels must be inspected and ring-tested before they are mounted to ensure that they are free from cracks or other defects. Rotate the wheel 45 degrees and repeat the test. Categories Featured Products More Info rmation.

Source: pinterest.com

Source: pinterest.com

Visual Inspection and Ring Test Hammering Test for grinding wheels Visual Inspection Perform visual inspection and check on the following issues before mounthing wheel. A 18 in or less B No less than 18 in C ¼ in. Rotate the wheel 45 degrees and repeat the test. Grinding experts call this the ring test and its something that should be done before mounting any wheel to an arbor. The ring test is designed to detect any cracks in a wheel.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title grinding wheel ring test by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.